-

Introduction:

QL-PCM Root Puncture Resistant-Type Polymer Modified Asphalt waterproofing membrane consists of high-grade asphalt in particular modification agent, import the root retarder to modification, block root, for high-strength fibre polyester tire body, surface coated with PE mucous membrane made of resistant to root type piercing modified asphalt waterproofing materials.

-

Product Features:

1. Technology is reliable, waterproof resistance root double-effect imported resistance agent resistance of modified asphalt system root, optimizing long fibre polyester tire body, form is given priority to with chemical resistance of root, root is complementary physical resistance of dual system, dual reliable waterproof resistance root.

2. Excellent performance, high tensile strength, high elongation, corrosion resistance, mildew resistance, good weather ability, good adaptability to basic shrinkage, deformation and cracking. Hot melt construction, cold and hot area can be applied, hot joint is more reliable and durable.

3. System health, and safety to the waterproofing and drainage plate storage of root, the geotextile collocation of waterproof system, solved the planting base dual requirement, waterproof and resistance to plant provides good drainage condition, storage system resistance to plant fertilization, ensure the healthy growth of plants.

-

Applications:

All kinds of industrial and civil buildings, planting roof, planting roof, balcony, roof, wall, etc. Need to be resistant to plant root puncture.

Construction:

1. Process flow: grass root Cleaning, repair, scraping cold bottom oil, nodal sealing, strengthening treatment, positioning, test paving, rolling materials thermal melting construction, inspection and acceptance. The base should be cleaned and patched, and the grass roots should be solid, clean, free of oil, dust, floatation and garbage, and the water rate of the grass roots will be less than 9%.

1. Process flow: grass root Cleaning, repair, scraping cold bottom oil, nodal sealing, strengthening treatment, positioning, test paving, rolling materials thermal melting construction, inspection and acceptance. The base should be cleaned and patched, and the grass roots should be solid, clean, free of oil, dust, floatation and garbage, and the water rate of the grass roots will be less than 9%.

2. Surface treatment agent at the grass-roots level : the drum or scraper blade coating treatment agent at the grass-roots level evenly on the base surface, shall not be piled up, leakage, make the first-line treatment evenly is full of all the water surface, first-line treatment reference usage: 1kg/m squared.

3. Node, strengthening treatment: according to the specification requirements, to attach to enhance the node location, such as Yin and Yang Angle, shutting, tube root, impinges mouth, deformation seam pipe, and so on, should also be set to avoid of post-cast strip, strengthening layer.

4. Positioning and testing: according to the situation of the construction site, make a reasonable positioning, determine the direction of the rolling material, and generally carry the rolling material from low to high in the direction of water flow.

5. Hot melt construction: the nozzle of nozzle flame is 300 - 400mm from the surface of the rolling material and the surface of the heating coil is evenly heated, and the rolling material can be rolled when it is black.

6. Side hot melt side roller, remove the air under the coil, make the coil and base surface sufficient, strong bond.

7. The lap width of the coil shall not be less than 80mm, the edge of the joint seam shall be suitable for the overflow of the modified asphalt of hot melt, and the roller shall be closed and tightly closed with the roller.

8. When the coil is closed, the coil head is bonded firmly, and it is pressed into the reserved groove, the pressure bar is pressed and sealed with the sealing paste.

9. After examination and acceptance of 6: check the construction of coiled material waterproof layer torn, punctured, bubble defects, such as repair parts should be the defect when placing the coil (150 mm) vertical and horizontal extension, mending plus coil should be covered with hot melt compaction, cream with sealing seam sealing side.

-

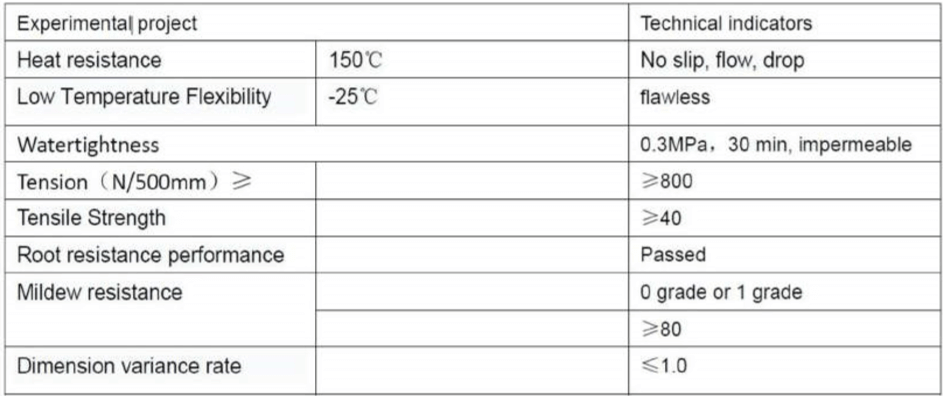

Technical Index:

Standard: JC/T 1075- 2008